Company Overview

Years of Experience

15

Factory size

5000㎡

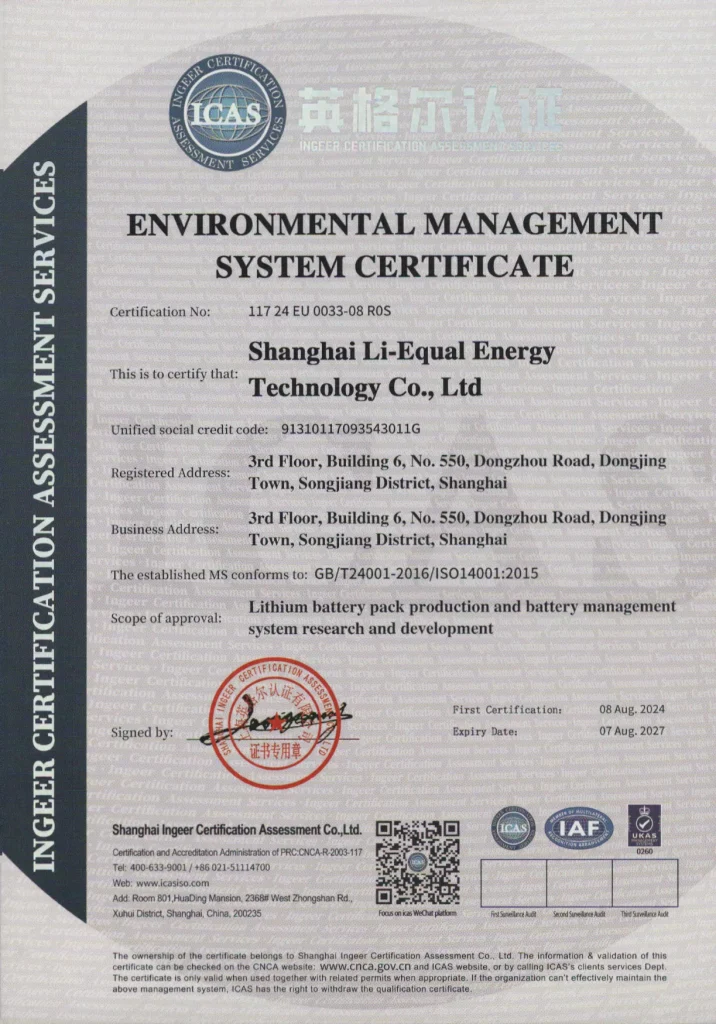

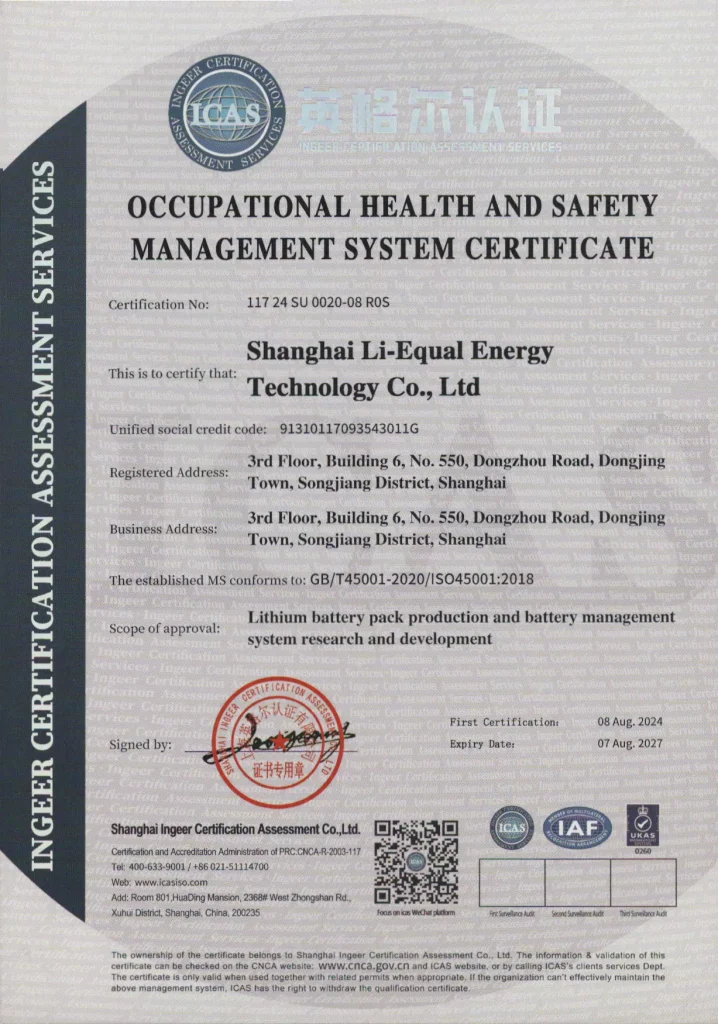

Quality certification system

ISO9001:2015

Development History

2014 Established

- Establish a Battery Management System (BMS) R&D team

- Reached a strategic cooperation agreement with Danish Lithium Balance Company (LIB) to be responsible for the company’s power management system

2015-2017 Upgraded

- Provide power batteries for the Shanghai Pudong maglev train project.

- Developed industrial robot batteries and successfully entered the brand’s automotive production site.

- Passed ISO9001 certification.

2018-2022 Steady improved

- In 2018, it was rated as a qualified supplier by the Shanghai Space Administration. Our company provides robot lithium batteries and charging solutions for aerospace intelligent manufacturing in confidential scenarios

- In 2022, the company was rated as a high-tech enterprise in Shanghai.

2023~ Achieve More

- Developed drone batteries.

- Continuously creating excellent results in fields such as drones and robots.

Design and engineering capabilities

We have experienced electrical engineers, structural engineers, and software engineers who ensure that all customized products meet various data indicators, making customization simple and efficient!

Manufacturing process

Our battery pack production process complies with industry standards and fully meets the process requirements.

Quality Control

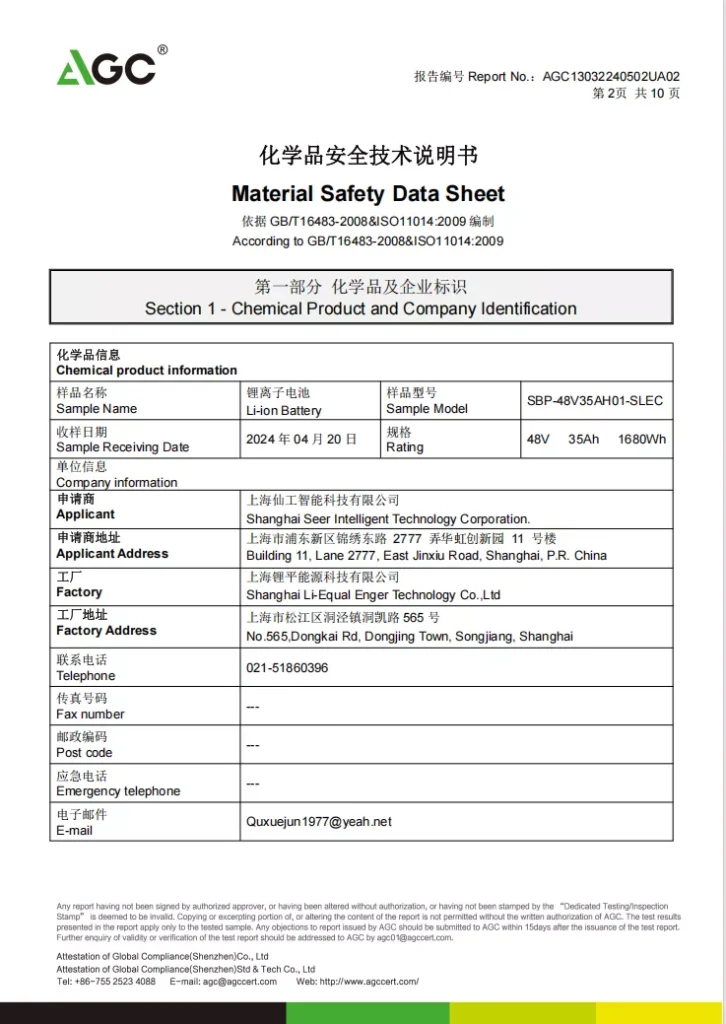

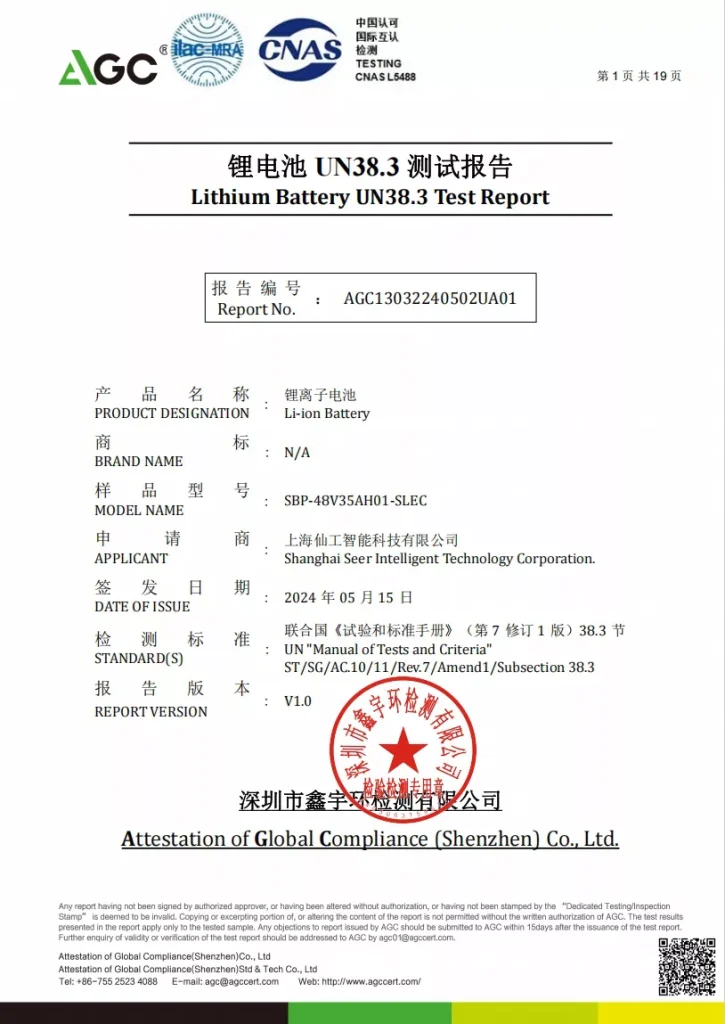

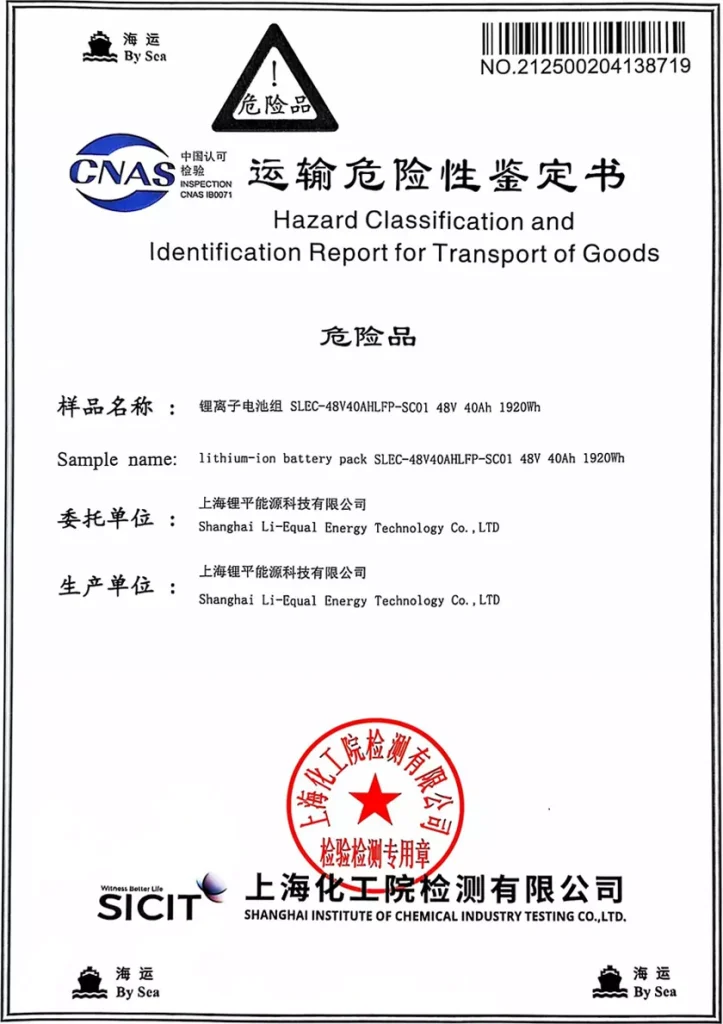

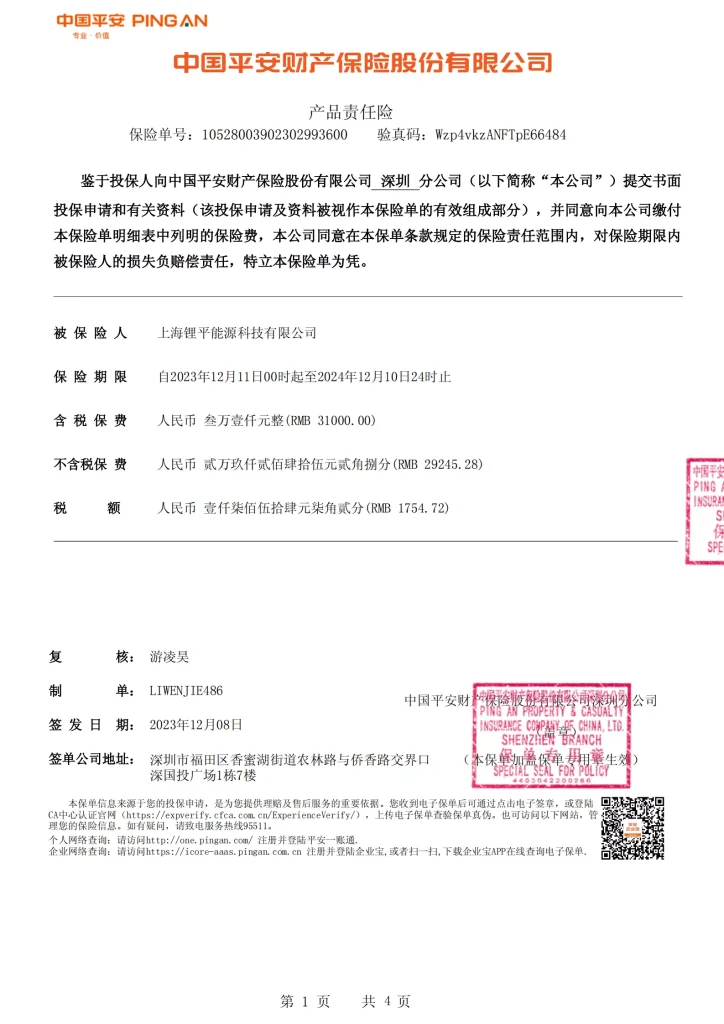

All of our production, from cell screening, welding, BMS testing, to battery charge and discharge cycle testing of the entire battery pack, undergoes strict quality control to ensure that every battery leaving the factory meets quality standards.

Innovation ability

Our BMS is constantly developing and innovating

Company Honor

Partner