UAV inspection is becoming increasingly prevalent across industries such as power utilities, oil & gas, and agriculture. To ensure efficient and reliable mission completion, a comprehensive UAV Inspection Battery System Solution covering design, selection, management, and maintenance is essential. Below is an integrated proposal.

Sample Cell Configuration

Example: 22.2V (6S) 25Ah

Cell Model: NCM 5000mAh 3.7V 18650/21700

Configuration: 6S5P (6 series, 5 parallel)

Total Energy: Approx. 555Wh

Estimated Weight: 2.5-3.0 kg (including structure & BMS)

- Overall System Architecture

1.1 Battery System Module

Lithium Battery Pack (e.g., NCM, LFP)

BMS (Battery Management System)

Pack Structural Design (Shock-proof, Water-resistant, Heat Dissipation)

1.2 Charging & Swapping System

Smart Charging Hub (Fast Charge, Auto-recognition)

Automated Swap Station (Robotic or Rail-based)

Expandable Solar Charging Module (for remote areas)

1.3 Battery Monitoring & Ops Management System

Cloud-based Battery Health Platform (SOC, SOH Monitoring)

Mobile App/Platform for Remote Diagnostics & Alerts

Data Reporting & Analytics (Lifecycle Prediction)

1.4 Backup & Dispatch System

Backup Battery Dispatch Mechanism (Mission-Battery Matching)

Integrated Flight Route Planning & Charging Schedule Sync

2. Battery Selection Guide

3. Key BMS (Battery Management System) Features

Real-time voltage, current, temperature monitoring

Charge/Discharge Protection (Over/Under Voltage, Overcurrent, Short Circuit)

SOC (State of Charge) Estimation & SOH (State of Health) Evaluation

Cell Balancing (Prolongs lifespan)

Data Logging & Upload (Supports Remote OTA)

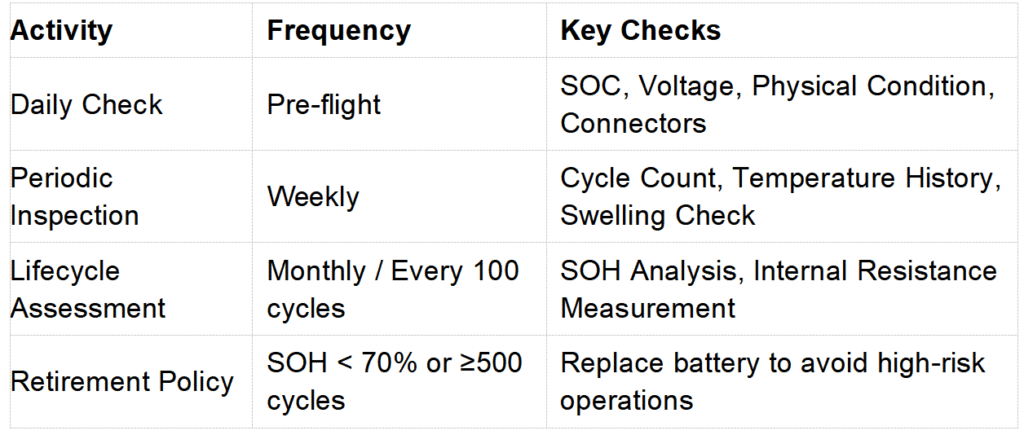

4. Battery Maintenance & Inspection Strategy

5. Automation Support

Unmanned Swap Station: Enables autonomous landing → bay opening → battery swap → takeoff. Uses RFID/battery ID for mission binding.

Smart Charging Station: Configurable charging modes (Slow/Fast/Maintenance), adaptive charging curves, remote control & alarm alerts.

6. Data Platform Capabilities (Cloud-ready)

GIS-based real-time battery distribution monitoring

Historical mission tracking & lifecycle usage curves per battery

AI-powered battery degradation trend prediction

Integration with flight dispatch to assign healthiest batteries for demanding missions

7. Safety & Compliance

Transportation certifications: UN38.3, MSDS

BMS complies with IEC 62660 / GB/T 34014

Flame-retardant materials; Pack meets impact resistance & IP rating standards

8. Typical Endurance Examples

9. Compatible UAV Types (Examples)

Medium-Large Multi-rotor Inspection Drones

Heavy-lift Hexacopters for Multi-role Missions

VTOL (Vertical Take-Off and Landing) Fixed-wing Drones

Specialized Inspection Drones for Power Towers & Wind Turbines

As a lipo battery manufacturer, UniquePower delivers a full range of UAV battery solutions. From consumer FPVs to commercial-grade drones, such as inspection drones,cleaning drones etc., If you have any questions or needs, Welcome to contact us at sales@uniquepower.net